PDM vs PLM: Which is Right for Your Business?

Table of contents

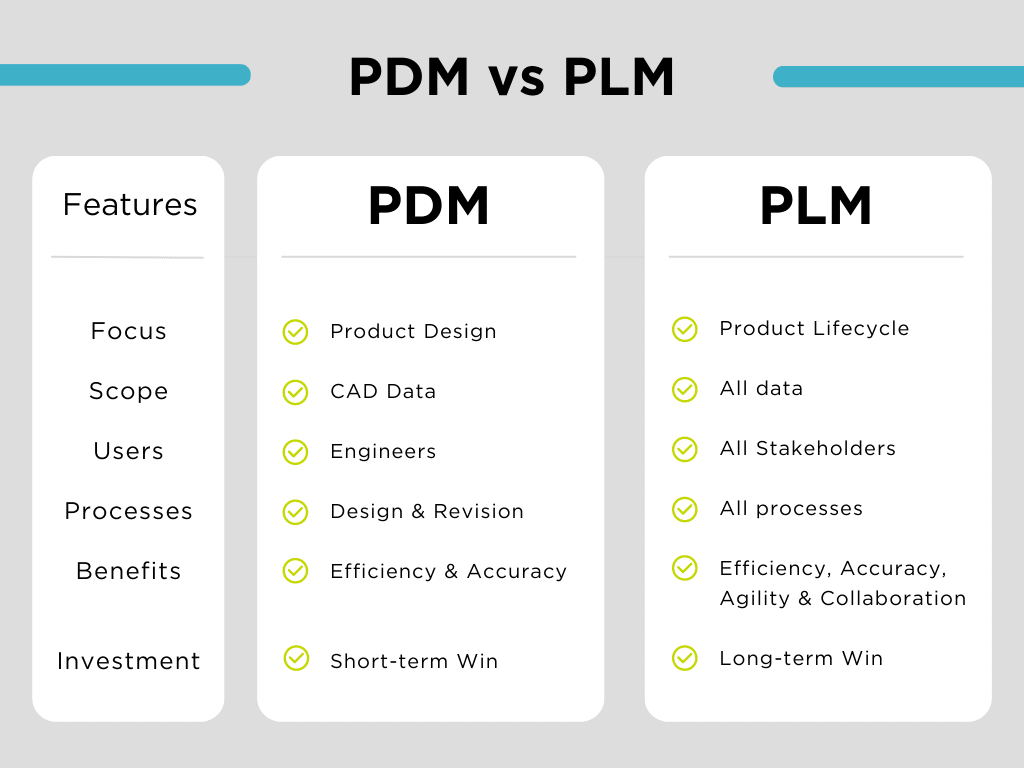

Product Data Management (PDM) and Product Lifecycle Management (PLM) are two software solutions that can help companies manage their product data. However, there are some key differences between the two systems. PDM is focused on managing design data, while PLM is a more comprehensive solution that also manages manufacturing, marketing, and other aspects of the product lifecycle.

In this blog post, we’ll discuss the differences between PDM and PLM, and how to decide which solution is right for your business. We’ll also compare some specific features in PDM vs PLM solutions, such as SmartTeam, SOLIDWORKS PDM, CATIA, and 3DEXPERIENCE.

PDM vs PLM: Points to Consider

Here are some of the reasons why choosing between PDM and PLM can be a difficult choice:

- The size and complexity of your company’s product development process: If your company is small or if you only need to manage product design data, then PDM may be a good choice for you. However, if your company is large or if you need to manage product data across the entire product lifecycle, then PLM may be a better choice.

- Your company’s budget: PDM systems are typically less expensive than PLM systems. However, PLM systems can offer a number of benefits that can help you to improve collaboration, reduce risk, and gain visibility into the product lifecycle.

- Your company’s needs and requirements: The best way to decide which solution is right for your company is to carefully consider your needs and requirements. This includes factors such as the size and complexity of your product development process, your budget, and your company’s culture.

What is PDM?

PDM stands for Product Data Management. PDM systems are designed to help companies store, track, and manage product design data. This data can include CAD files, 3D models, engineering drawings, and other documentation.

PDM systems offer several benefits, including:

Improved collaboration: PDM systems make it easy for engineers to share and collaborate on product design data.

Increased efficiency: PDM systems can help to streamline product development processes and reduce the risk of errors.

Improved traceability: PDM systems can help to track the history of product design data, which can be helpful for compliance and auditing purposes.

What is PLM?

PLM stands for Product Lifecycle Management. PLM systems are a more comprehensive solution than PDM systems. They not only manage product design data, but they also manage manufacturing, marketing, and other aspects of the product lifecycle.

PLM systems offer a few benefits, including:

Improved visibility: PLM systems give companies a single view of the product lifecycle, which can help to improve decision-making.

Increased collaboration: PLM systems make it easy for different departments within a company to collaborate on product development.

Reduced risk: PLM systems can help to reduce the risk of errors and recalls by providing a central repository for product data.

Keep learning about PLM with our full blog post, “What is PLM?”

Comparing PDM to PLM

SmartTeam PDM

SmartTeam is a PDM software solution that is designed for small and medium-sized businesses. It is easy to use and affordable, making it a good option for companies that are just starting out with PDM. SmartTeam offers a number of features, including:

Document management: SmartTeam can store and manage a variety of document types, including CAD files, BOMs, and engineering drawings.

Version control: SmartTeam allows you to track changes to documents, so you can always revert to a previous version if necessary.

Collaboration: SmartTeam makes it easy to collaborate with others on documents, making it a good option for companies that work with remote teams.

SOLIDWORKS PDM

SOLIDWORKS offers both PDM and PLM solutions based on different deployment methods. As a PDM solution, it’s a more powerful and feature-rich solution than SmartTeam, but it’s also more expensive. SOLIDWORKS PDM offers a number of features, including:

Document management: SOLIDWORKS PDM can store and manage a variety of document types, including CAD files, BOMs, and engineering drawings.

Version control: SOLIDWORKS PDM allows you to track changes to documents, so you can always revert to a previous version if necessary.

Collaboration: SOLIDWORKS PDM makes it easy to collaborate with others on documents, making it a good option for companies that work with remote teams.

Manufacturing: SOLIDWORKS PDM can also be used to manage manufacturing data, making it a good option for companies that manufacture products.

SOLIDWORKS PLM

As a PLM solution, SOLIDWORKS can be deployed on cloud, or via the Collarborative Designer role for 3DEXPERIENCE. Here are some of the benefits of deploying SOLIDWORKS as part of the 3DEXPERIENCE platform:

Improved collaboration: The 3DEXPERIENCE platform makes it easy to collaborate with others on product data. You can share files, track changes, and discuss your work in real time.

Increased visibility: The 3DEXPERIENCE platform gives you a single view of your product data. This makes it easy to see how different parts of your product fit together, and it also makes it easy to track the progress of your product development projects.

Enhanced security: The 3DEXPERIENCE platform is a secure environment for storing and managing product data. Your data is protected from unauthorized access, and you can control who has access to your data.

CATIA PLM

CATIA provides a PLM software solution that is designed for large and complex product development projects. It is the most powerful and feature-rich solution on this list, but it is also the most expensive. CATIA offers a number of features, including:

Product data management: CATIA can store and manage a variety of product data, including CAD files, BOMs, and engineering drawings.

Version control: CATIA allows you to track changes to product data, so you can always revert to a previous version if necessary.

Collaboration: CATIA makes it easy to collaborate with others on product data, making it a good option for companies that work with remote teams.

Manufacturing: CATIA can also be used to manage manufacturing data, making it a good option for companies that manufacture products.

3DEXPERIENCE PLM

3DEXPERIENCE provides a PLM software solution that is designed for companies of all sizes. As a cloud-based solution, 3DEXPERIENCE makes it easy to access and work with your data from anywhere. 3DEXPERIENCE offers a vast variety of features, some highlights include:

Product data management: 3DEXPERIENCE can store and manage a variety of product data, including CAD files, BOMs, and engineering drawings.

Version control: 3DEXPERIENCE allows you to track changes to product data, so you can always revert to a previous version if necessary.

Collaboration: 3DEXPERIENCE makes it easy to collaborate with others on product data, making it a good option for companies that work with remote teams.

Manufacturing: 3DEXPERIENCE can also be used to manage manufacturing data, making it a good option for companies that manufacture products.

When to Choose PDM vs PLM

If your company is small or if you only need to manage product design data, then PDM may be a good choice for you. PDM systems are typically less expensive than PLM systems, and they are easier to implement.

When to Choose PLM vs PDM

If your company is large or if you need to manage product data across the entire product lifecycle, then PLM may be a good choice for you. PLM systems offer a number of benefits that can help you to improve collaboration, reduce risk, and gain visibility into the product lifecycle.

Migrating from PDM to PLM

If you are considering migrating from PDM to PLM, there are a few things you should keep in mind.

First, you need to make sure that your company is ready for the transition. PLM systems are more complex than PDM systems, so you need to make sure that your company has the resources to implement and manage a PLM system.

Second, you need to choose the right PLM solution for your company. There are a few different PLM solutions available on the market, so you need to carefully evaluate your needs and requirements before making a decision.

Third, you need to plan your migration carefully. This includes identifying your data, migrating your data, and testing your migration.

In Our Experience…

PDM and PLM are two different software solutions that can help companies manage their product data. PDM is a more focused solution that is designed to manage design data, while PLM is a more comprehensive solution that can manage all aspects of the product lifecycle. It might be helpful to speak to an expert if you are having trouble deciding between PDM and PLM. We can help you to understand the differences between the two systems and to determine which solution is right for your company.

If you are not sure which solution is right for your business, reach out to one of our experts for help.